How important Is material strength for hand tools?

What is this about?

How important is material strength for hand tools? How stressed are tools in reality? How strong are tool steels compared to other steels? What difference make higher strength steels for tools practically? Do top brands use better steels and does it justify their heigher price? Many questions, so let's look into them one by one, but in a somewhat different order.

How stressed are hand tools in normal operation?

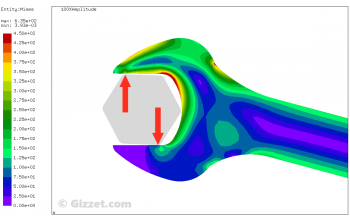

The short answer is: tools see quite significant stress loads in normal operation. The figure below shows the stresses of a 16 mm open-end wrench key when applying a torque of 16 Nm. That is about 30% of the nominal tightening torque of an M10 screw (49 Nm) which has a 16 mm hex head. How much is 16 Nm you might ask? A torque of 16 Nm is generated you pull at the end of the wench key (200 mm long) with a force equivalent to 8 kg.

The red colored areas in the figure are the zones with the highest stresses (up to 635 MPa). This stress level is already above the yield stress limit of average construction steels. Luckily the yield stress limit for quality tool steels is much higher. How high are they?

How strong are tool steels actually?

Most tool makers do not publish details about the steel grades which they use, but some do. In Germany a common tool steel grade used for tool such as wrench keys is 31CrV2 (EN steel number 1.2208). The obtained strength depends on the hardening and tempering process and is usually between 1200-1400 MPa, but values as high as 1800 MPa can be reached. Also the forging process usually increases the strength of steels. There is much more to talk about steels, so please stay tuned and check out our other posts on this topic.

Tool breakage?

If the torque load in the above example is increased 3 times to 49 Nm, which is the nominal tightening torque of 8.8 grade M10 screws, the peak stresses in the wrench key reaches the yield stress limit of good tool steels. As long as the plastified zones (red and orange in the image) remain small, the jaws will not deform permantently. At that point a force equivalent to 24 kg must be applied to the end of the wrench key. Still feasible but it starts to get a bit tiring on the hand.

Even greater torque loads can be applied by attaching an extension to the wrench key. Under such circumstances the stresses will eventualy reach a level, where the jaws become fully plastified and the tool would start to deform permanently. Bad quality tool steels might have very little plastic deformation capacity and that would result in brittle fracture. This will send the wrench key and its pieces flying off at high speed and might cause serious injury.

Why not just adding more material so the tool would no break you think?

Why high strength steels are really important?

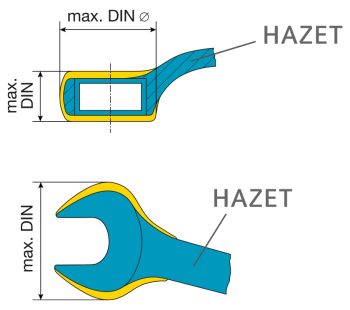

In fact the opposite is desired! The true benefit for using high strength tool steel is, that tools can be made slimmer and lighter. For those working with tools all-day long, the lighter handling makes a big difference. Also the toolbox gets lighter. Secondly and even more important: slimmer tool heads give better access as well as more wrench movement in hard-to-reach and confined screw locations.

The example below shows Hazet makes wrenches slimmer than required by DIN. And the same goes for Stahlwille, which sometimes bilds even slimmer.

Reduced tool wear

Metal strength and hardness are closely related. How exactly and what hardness means exactly and how it is measured is discussed in more detail in other posts. Please have a look at the links below. High hardness reduces wear and surface abrasion. In case of pliers or cutting tools in general, it keeps the cutting edges sharper for a longer time.

Conclusion

If you want to enjoy your tools for a long time, then choosing tools made of high strength tool steel is our recommendation. For that reason we are carrying out our own Gizzet hardness testing for all the tools which we are selling in our webshop. The results can be found on each product page as well as in our tool tests and reviews in this blog. We hope it will help you to choose the right tools!

Like this post? Please share!

If you like this post and think others might find it useful too, please share it on Facebook, Twitter etc.

Questions? Comments?

If you have questions or comments, please leave us a comment below. We really like to hear back from you! Getting feedback is what keeps us going to write many more articles.

0 Comment

Leave a Comment

Your email address will not be published. Required fields are marked *

![[ Stahlwille ]](https://gizzet.com/en/media/wysiwyg/banners/stahlwille_aerospace_A01_en.png)