What is DIN?

What does DIN mean?

DIN is the abbreviation for "Deutsches Institut für Normung", which means German Institute for Standardization.

Why standards? – Some history ...

A4 paper fits into every printer and a M8 screw fits any M8 nut. What seems obvious today was not so much the case more than 100 years ago. At that time most manufacturers had their own independent standards and sizes for components such as screws on pins. When the German army had to source pins for the famous machine gun "08/15" during the 1st world war the parts supplied by different makers often did not fit. As a result DIN was founded in 1917, this means more than 100 years ago.

The first "DIN 1"

DIN number 1 actually exists! On March 1st, 1918 the first standard was published as DI Norm 1 for taper pins (see below):

In the beginning DIN was focussing on machine parts and tools.

But soon the field for DIN standards was enlarged. For example in the year 1922 the DIN A4 paper size standard was created − the paper size which is used today in most of the world.

34,265 standards – Some examples

In the year 2018 the number of DIN standards had grown to a total of 34,265. DIN standards now cover a wide range of fields - here are some examples:

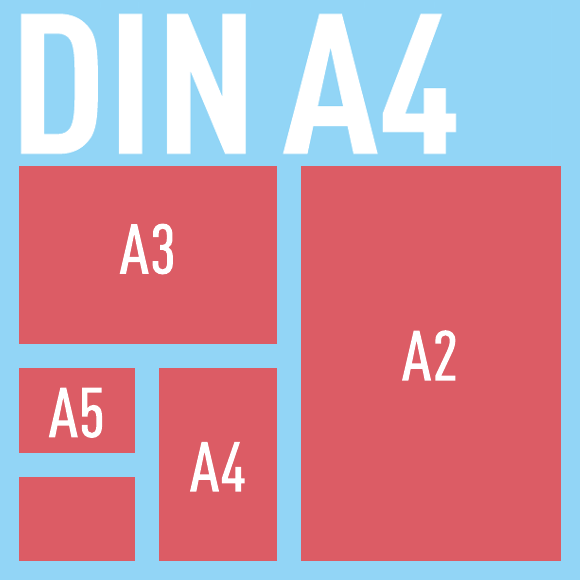

Paper sizes

Paper sizesDIN 476

Hexagon bolts

Hexagon boltsDIN 933

Container

ContainerDIN 15190

Baby soother

Baby sootherDIN EN 1400

Bicycle helmet

Bicycle helmetDIN EN 1078

Cyber security

Cyber securityDIN EN ISO 27001

DIN-standards cover technical fields from screws to shipping containers, but also non-technical fields such as baby soothers, bicycle helmets or even network cyber security. Assuring safety is an important aspect. For example baby soothers made accoring to DIN EN 1400 have to have holes to avoid Suffocation if the soother is swallowed by the child.

Examples for tool standards

Here are some of the tools standards for tools, which can find in our webshop:

DIN 3110 – Double open-end wrench keys

DIN 3113 – Combination wrench keys

DIN 838 – Double-ended ring deep crank head wrench keys

Links:

- https://www.din.de/

- Wikipedia.org – ドイツ工業規格

Questions & answers:

Q: Are DIN-standards binding by law?

A: No, they are recommendations and are regularely adapted and exceeded

DIN-standards are recommendations and there is no need for tool makers to follow them stricktly. In fact many makers exceed the requirements defined in the standards such as for example reducing the allowed tolerances. Sometimes they improve the products by using better steels to make the tools slimmer and lighter which improves accessibility and handling.

0 Comment

Leave a Comment

Your email address will not be published. Required fields are marked *

![[ Stahlwille ]](https://gizzet.com/en/media/wysiwyg/banners/stahlwille_aerospace_A01_en.png)