- Description

-

Details

Specification:

- Set of 10 double open-end wrench keys

- Chrom Vanadium alloy steel

- Surface matt chrome-plated

- Slim heads

- Shank with sturdy HAZET double-T-profile

- Head setting: 15°

- According to German DIN 3110/ISO 10102 standard – DIN とは?こちらをご覧ください)

- Key sizes: 6 x 7 • 8 x 9 • 10 x 11 • 12 x 13 • 14 x 15 • 16 x 17 • 18 x 19 • 21 x 22 • 24 x 26 • 27 x 32

- Size (L x W x H): 330 x 80 x 40 mm

- Weight: 1.40 kg

Dimensions

wrench size a

[mm]b1

[mm]b2

[mm]l

[mm]6 x 7 3.5 15.1 17.1 121.3 8 x 9 3.8 18.5 21 139 10 x 11 4.6 23.2 25.2 155.7 12 x 13 5.1 27.1 29.1 172.7 14 x 15 5.7 30.9 32.8 187.8 16 x 17 6 34.8 37 205.7 18 x 19 6.7 38.6 40.6 221.2 21 x 22 7 44.8 46.8 238 24 x 26 7.8 50.9 54.9 269.4 27 x 32 9.1 58 67.3 303.8 HAZET high precision

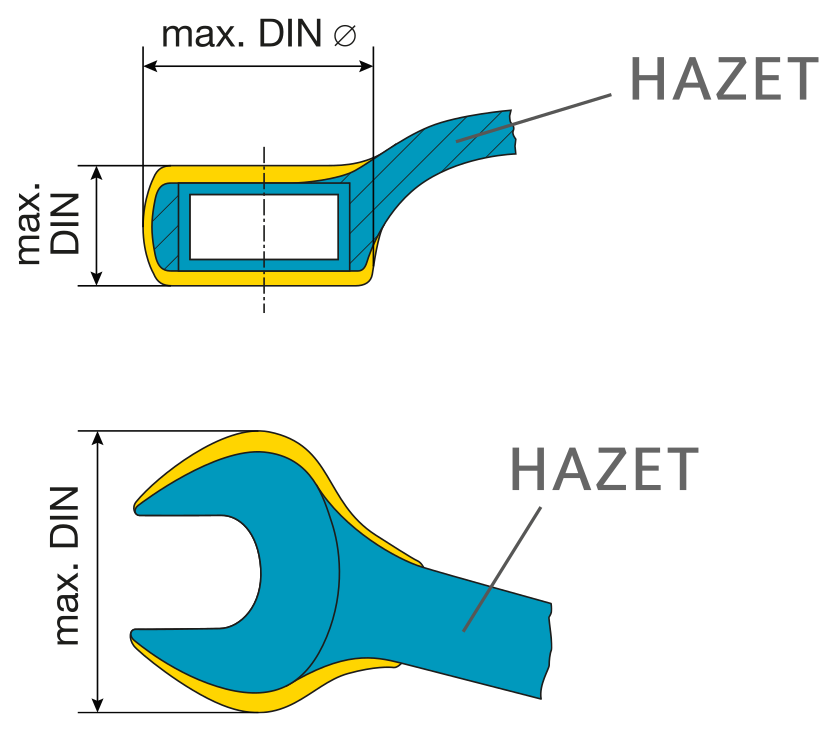

HAZET tolerance

DIN standard permissible tolerance

HAZET wrenches are manufactured with highest precision to meet narrow tolerances.

Why is a proper fit of screws and wrench so significant?

- A tight fit reduces the stresses, both on the wrench as well as the screw

- The load-bearing capacity of the wrench is therefore increased

- The edges of screw heads will not wear- or round-off

- The risk to slip off is also reduced

- All this results in a reduction of risk of injury and damage

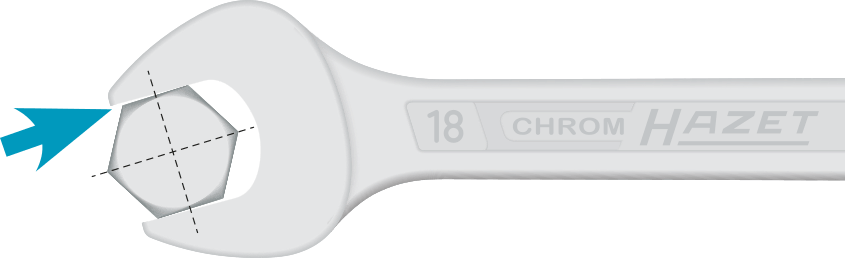

HAZET slim design

The optimized selection of material composition enables a slim wrench construction.

The benefits for the user are:

- Better tool access and more wrench movement especially in hard-to-reach screw locations

- Weight reduction of the wrenches

- The lower weight improves wrench handling as well as lower carrying weight of the tool bags

- Despite the slim open-end and box-end head designs, the load-bearing capacity is not reduced

- For the entire range of wrenches the DIN/ISO load-requirements are all exceeded significantly

HAZET chrome plating

HAZET uses an elaborate and optimized matt surface chrome plating for its tools which have the following benefits:

- Matt chrome plating adheres best to steel

- Therefore best corrosion protection (due no flaking-off or cracks)

- Good and secure grip even with dirty or oily hands

- Glare-free optics

- Elegant looks

HAZET wrench manufacturing

Decades of continuous development and optimization of the wrench and tool manufacturing process are one of the pillars of the success of HAZET. The process spans several important aspects such as:

- the selection of the steel alloy composition and reliable supplying partners

- the drop forging process which has a strengthening effect through crystal structure concentration

- a careful hardening and tempering process, which enables the full potential of hardness and strength yet retaining ductility at the same time

- the galvanic protection coating, which will not detach or flake-off even under the roughest working conditions.

Summary of a HAZET wrench creation:

(similar for all HAZET wrench types and models)

Step 1 – Cut to size

Step 2 – Forging

Step 3 – Blank trimmed

Step 4 – Blank sand blasted

Step 5 – Open-end head milled

Step 6 – Box-end head broached

Step 7 – Fine-ground (heads and handle)

Step 8 – Hardened and tempered

Step 9 – Vibratory ground

Step 10 – Sand blasted

Step 11 – Head polished

Step 12 – Nickel- and chrome-plated

FINISHED

- Reviews

-

Call us: 050-5846-0447

10:00 - 18:00 (Mo-Fr)

![[ Stahlwille ]](https://gizzet.com/en/media/wysiwyg/banners/stahlwille_aerospace_A01_en.png)